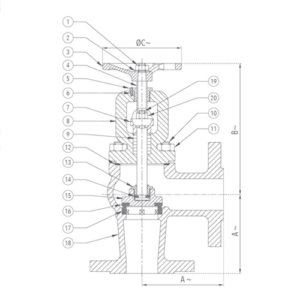

Materials

| P.No. | Name of Part | Material of Construction | Specification | Quantity |

|---|---|---|---|---|

| 1 | Nut | Carbon Steel | – – – | 1 |

| 2 | Washer | Carbon Steel | – – – | 1 |

| 3 | Handwheel | Cast Iron | IS 210 Gr. FG 200 | 1 |

| 4 | Stem | Stainless Steel | ASTM 276 Type 410 | 1 |

| 5 | Yoke Bush | Bronze | IS 318 Gr. LTB 2 | 1 |

| 6 | Locking Screw | Carbon Steel | – – – | 1 |

| 7 | Gland Flange | Cast Iron | IBR 86-93 Gr. A | 1 |

| 8 | Bonnet | Cast Iron | IBR 86-93 Gr. A | 1 |

| 9 | Gland Packing | Braided Graphited Asbestos | IS 4687 | – |

| 10 | Studs | Carbon Steel | IS 1367 | As Reqd. |

| 11 | Nuts | Carbon Steel | IS 1367 | As Reqd. |

| 12 | Gasket | Steam Jointing Sheet | IS 2712 Gr. W/3 | 1 |

| 13 | Stem Nut | Stainless Steel | ASTM A 276 Type 410 | 1 |

| 14 | Stem Ring | Stainless Steel | ASTM A 276 Type 410 | 1 |

| 15 | Disc | Cast Iron | IBR 86-93 Gr. A | 1 |

| 16 | Seat Ring | Stainless Steel | ASTM A 276 Type 410 / ASTM A 182 Gr. F6a | 1 |

| 17 | Body Seat Ring | Stainless Steel | ASTM A 276 Type 410 / ASTM A 182 Gr. F6a | 1 |

| 18 | Body | Cast Iron | IBR 86-93 Gr. A | 1 |

| 19 | Nuts | Carbon Steel | IS 1367 | 2 |

| 20 | Bolts | Carbon Steel | IS 1367 | 2 |