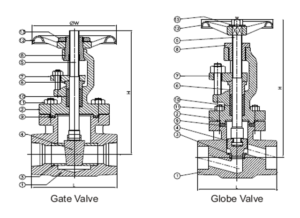

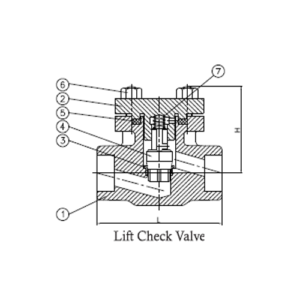

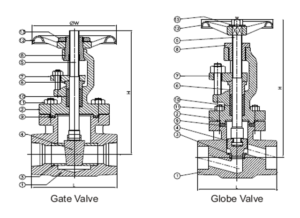

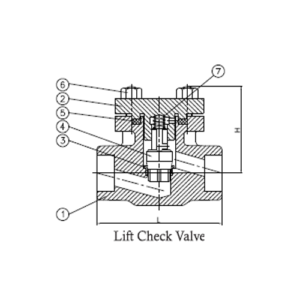

The IV Forged range of Gate, Globe & Check valves incorporates state of the art design features to provide a rugged construction, reliable operation and long life; suitable for all the segments of the process industries including chemical, petrochemicals, pharma, steel, alumina, power plants and common utilities.

The valves are available in Socket weld, Screwed end, Butt weld & Flange end connections. Valves can be provided with special cleaning for oxygen service, NACE Compliant materials for sour service in the petroleum industries etc.

The valves can be provided with a motor operation for Gate & Globe valves wherever required.

| Size Range |

1/2″ (15NB) to 2″ (50NB) |

| Class Rating |

#800, #1500, #2500 |

Technical Specifications

API TRIM NO. & SEAT HARDFACING

API 600

Trim No. |

Nominal Trim |

Material Type |

Body Seating Surface |

Wedge Seating Surface |

Back Seat |

1 |

F6 |

13% Cr |

13% Cr |

4 |

Hard F6 |

Hardfaced with 13% Cr Steel

|

Hardfaced with 13% Cr |

5 |

Hardfaced |

Hardfaced with Co-Cr-W Alloy |

Hardfaced with Stellite 6 |

8 |

F6 & Hardfaced |

13% Cr Steel & Hardfaced with Co-Cr-W Alloy |

Stellite 6 |

13% Cr |

Stellite 6 / 13 % Cr |

Recommended Body/Bonnet & Trim Material For High Temperature Services (Water/Steam)

| Temperature |

Body / Bonnet Materials |

API Trim No. |

Up to 800 0F

(427 0C) |

A 216 Gr. WCB, A 217 Gr. WC6, A 217 Gr. WC9 |

1, 4, 5, 8 |

Above 800 0F

(427 0C)

& Up to 1000 0F

(540 0C) |

A 217 Gr.WC6,

A 217 Gr.WC9 |

5 & 8 |

Above 1000 0F

(540 0C) |

A 217 Gr.WC6, A 217 Gr.WC9 |

5 |

|

| Sr. # |

Part

Name |

| 1 |

Body |

| 2 |

Bonnet |

| 3 |

Seat |

| 4 |

Disc / Wedge |

| 5 |

Spindle |

| 6 |

Gland |

| 7 |

Gland

Flange |

| 8 |

Yoke

Sleeve |

| 9 |

Gasket |

| 10 |

Packing |

| 11 |

Hardware |

| 12 |

Handwheel |

| 13 |

Handwheel Nut |

|

| Sr. # |

Part

Name |

| 1 |

Body |

| 2 |

Cover |

| 3 |

Seat |

| 4 |

Plug |

| 5 |

Gasket |

| 6 |

Hardware |

| 7 |

Spring |

|