Product Specifications

| Size | 10mm(3/8″) to 75mm(3″) |

|---|---|

| End Connection | Standard-G-ISO-228 (BSP-F), Optional -NPT |

| Body Material | Standard – SS ASTM A351 Gr.CF8. Optional – SS ASTM A351 Gr.CF8M. |

| Body Test Pressure | 40 Bar. (Refer to table below). |

| Max. Wkg. Pressure | 12 bar (refer table) |

| Seat Material | Std: PTFE, Optional – Viton. |

| Core Tube Nut | St. St. 304/ St. St. 316. |

| Plunger & Stopper | St.St.430FR |

| Spring | St.St.302 |

| Shading Ring | Copper |

| Temp. (ambient) | 42Deg.C. |

| Max. Wkg. Tempreture | (-)5 to 120 Deg. C. |

| Voltage (AC) | 230, 110, 48, 24V-50/60 Hz. |

| Voltage (DC) | 24, 110, 240V. |

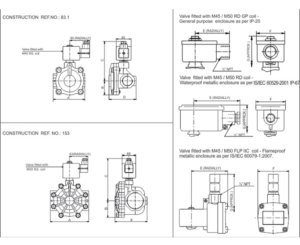

| Enclosure | General Purpose (IP20), Weatherproof -RD-WP-67 Flameproof-RD-FLP-IIC+WP67 |

| Approvals | KLPL/PESO/CE/ATEX/BIS |

| Differential Pressure | 2 to 24 bar |

| Coil Insulation | Class ‘H’ upto 155Deg.C. |

| Fluids | Air,Water,Gas,light Oil,heavy oil,Mild corrosive fluid,etc. |

| Manual Override | Only for 9100F-Normally Closed Valve. Not available for 9120F Normally Open Valve. |

| Optional Feature | Mounting Bracket. |

| Sales Point | Most reliable,maintanance free,on-off valve in our range. |

| Application | Chemical, textile, Cement machinery, combustion equipments, air dryer, cleaning equipments & other, Not Suitable for steam duty. |

| Mounting | In horizontal pipeline; keeping solenoid upright & vertical. |

| Temperature of Fluid | -5° C to 120° C |

| Note | 1. Use of filter in the inlet side is highly recommended. 2. Not Suitable for back pressure from outlet side. |